O Distrito Sanitário Central Contra Costa (Central San), que atende cerca de 500.000 moradores e mais de 15.000 empresas no condado de Contra Costa, Califórnia, enfrenta um desafio regulatório. O Conselho Regional de Controle de Qualidade da Água da Baía de São Francisco apresentou um mandato exigindo uma redução de 40% no nitrogênio inorgânico total (TIN) para Central San em 2034. A estação de lodo ativado convencional existente é projetada para remoção de sólidos e orgânicos e não consegue remover nitrogênio. Estima-se que as soluções tradicionais de atualização de tratamento, como a construção de novas bacias de aeração e clarificadores, custem aproximadamente US$ 700 milhões, uma opção proibitivamente cara, ainda mais complicada pela presença de solo contaminado no local de expansão proposto.

Para enfrentar esse desafio, a Central San explorou a tecnologia de reator de biofilme aerado com membrana (MABR) como uma alternativa inovadora aos processos de tratamento convencionais. A Central San fez uma parceria com a Veolia para teste piloto de seu sistema ZeeLung MABR, que permite a intensificação do processo – obtendo mais tratamento dentro da infraestrutura existente. A MABR usa membranas permeáveis a gás para fornecer oxigênio diretamente a um biofilme que cresce na superfície da membrana, criando condições favoráveis tanto para nitrificação quanto para desnitrificação. Os cartuchos MABR ZeeLung são imersos em tanques existentes para aumentar a capacidade de remoção de nitrogênio de um sistema convencional de lodo ativado.

De abril a de novembro de 2024, um sistema piloto ZeeLung MABR (2,5-6 galões por minuto) foi operado em Central San com os seguintes objetivos:

- Confirmar a capacidade do biofilme MABR de remover amoníaco, apesar da presença de cianeto da incineração de sólidos que é conhecido por inibir os processos convencionais de nitrificação.

- Determinar a taxa de remoção de amoníaco enquanto opera em baixos tempos de retenção de sólidos (SRTs).

- Testar o controle de espessura do biofilme sob condições variadas.

- Identificar o local ideal para a implementação em escala total do MABR ZeeLung.

Resultado

O estudo piloto demonstrou com sucesso que a tecnologia ZeeLung MABR pode fornecer a redução de TIN necessária enquanto utiliza a infraestrutura de tratamento existente da Central San. As principais conclusões incluíram:

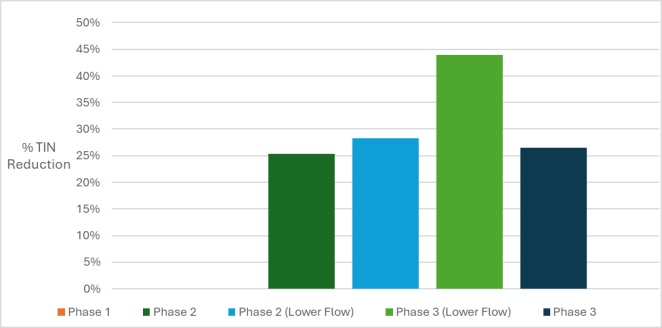

- A meta de 40% de redução de TIN foi alcançada com o uso do MABR, que pôde ser melhorado com a integração total à estação.

- Formação consistente de biofilme e nitrificação apesar da exposição ao cianeto, um conhecido inibidor biológico da remoção de nitrogênio.

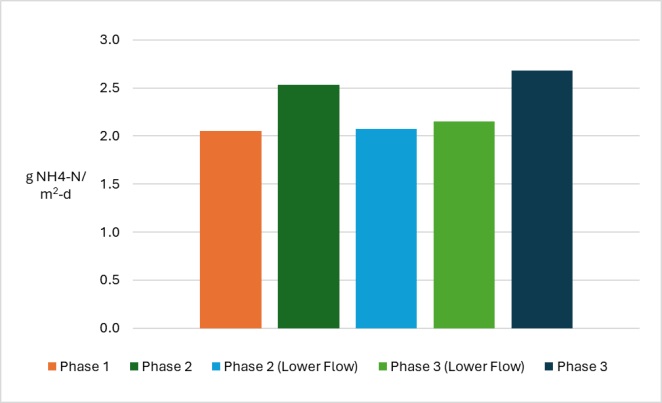

- As taxas de remoção de amoníaco atingiram a meta de 2 gramas por metro quadrado de área de superfície da membrana por dia.

- Maiores taxas de carregamento de carbono solúvel melhoraram a eficiência de redução de TIN.

- O desempenho estável foi mantido mesmo sob as condições mais desafiadoras.

Esses resultados são de um piloto de sete meses operando a 4 galões por minuto e validaram o MABR ZeeLung como uma solução de conformidade viável e econômica que evita grandes construções. Testes abrangentes em escala real, programados para 2026, fornecerão dados adicionais de desempenho.

|

Figura 1: Redução de TIN durante as fases piloto 2 e 3. Uma remoção de TIN superior a 40% foi observada na Fase 3, quando carbono suficiente estava disponível para desnitrificação no biofilme |

Figura 2: Taxas de nitrificação MABR nas fases piloto. As fases tiveram taxas de carregamento e fontes de alimentação variadas, onde a fase 1 teve a menor carga de carbono e cianeto e a fase 3 teve a maior. |

Conclusão:

Ao aproveitar a tecnologia MABR ZeeLung, a Central San está posicionada para atender às futuras regulamentações de remoção de nutrientes de maneira econômica e sustentável. Essa abordagem não apenas minimiza as despesas de capital, mas também maximiza a eficiência dos ativos de tratamento existentes, estabelecendo um precedente para soluções inovadoras de gerenciamento de efluentes na Bay Area e em toda a indústria.