Eletrodiálise bipolar (BPED)

Para recuperação de fluxos de salmoura para produzir produtos ácidos e cáusticos

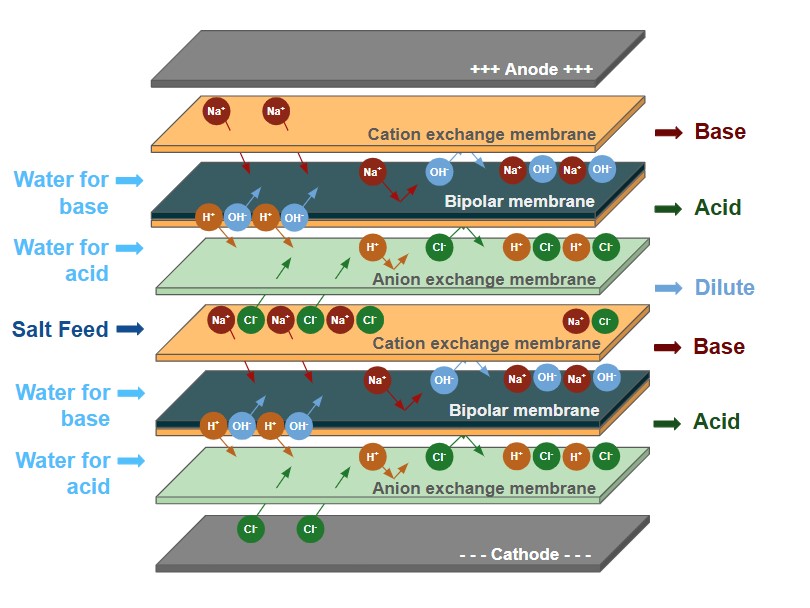

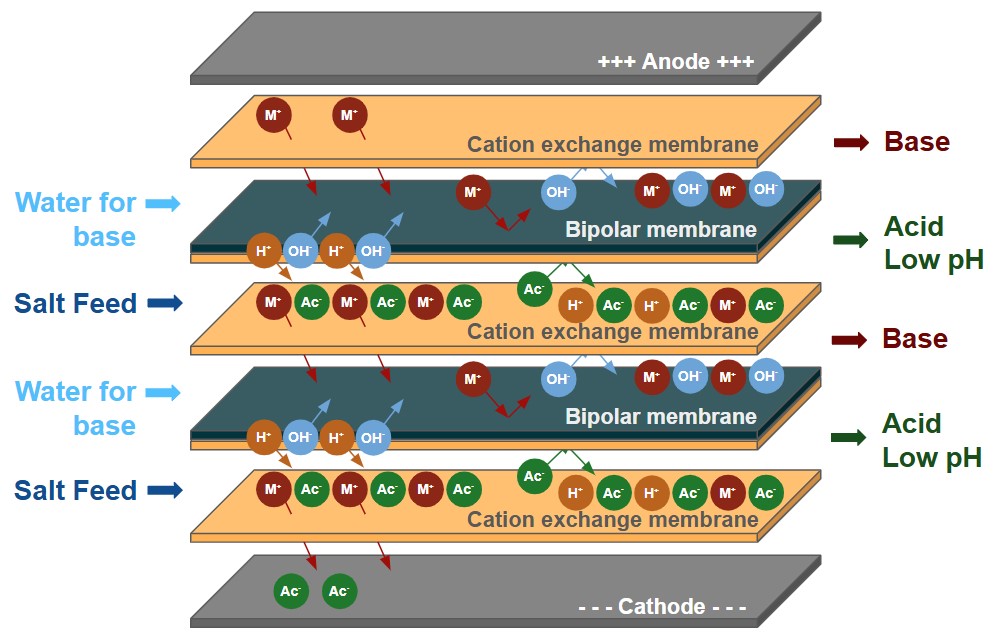

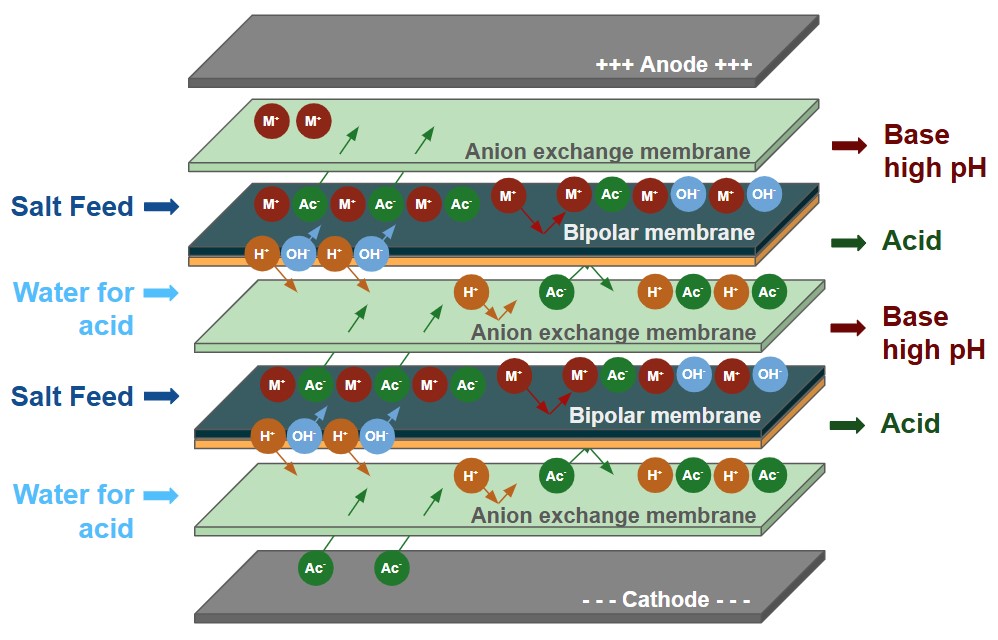

A eletrodiálise bipolar usa os princípios básicos da eletrodiálise, mas introduz uma membrana bipolar que divide a água em H+ e OH- dentro de uma pilha de eletrodiálise. This allows the removed salts to be converted in their acid and/or base products.

A BPED da Veolia pode ser usada em várias aplicações, incluindo produção de ácido orgânico, ajuste de pH em bebidas ou no uso de salmoura industrial para gerar derivados ácidos e cáusticos com valor agregado.